Computer-aided repair design (CARD) revolutionizes auto repair by digitizing measurements, creating 3D models, and streamlining planning. It enhances painting accuracy, preserves vehicle aesthetics, and increases resale value while simplifying complex repairs. Integrating CARD software requires aligning it with specific business needs, skills, and future goals to maximize precision and efficiency in body work and restoration.

“Revolutionize your repair process with Computer-Aided Repair Design (CARD). This technology offers precision and efficiency in managing complex repairs. In this guide, we’ll walk you through integrating CARD into your workflow seamlessly. First, understand the basics of CARD and its benefits. Next, learn how to choose software tailored to your needs. We’ll then explore strategies for a smooth integration process, ensuring your existing practices enhance repair design accuracy and speed.”

- Understanding Computer-Aided Repair Design Basics

- Choosing the Right Software for Your Needs

- Seamlessly Integrating into Existing Workflows

Understanding Computer-Aided Repair Design Basics

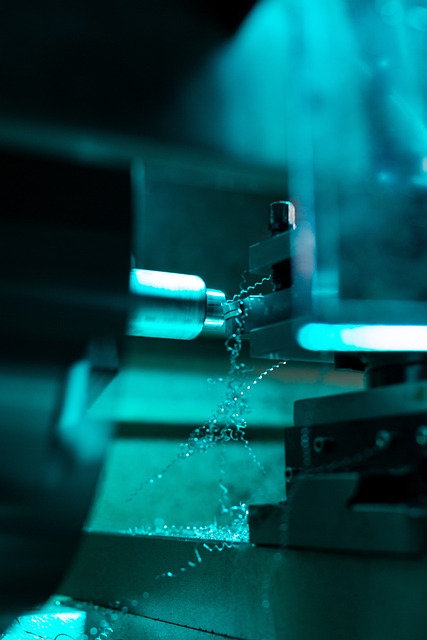

Computer-aided repair design (CARD) is a game-changer for any automotive workshop or fleet repair service. It’s more than just software; it’s a system that streamlines and enhances the entire car body repair process, from measurement and design to painting and final assembly. At its core, CARD uses digital tools to take precise measurements of damaged vehicle parts, creating detailed 3D models that can be manipulated virtually. This allows technicians to plan repairs more efficiently, identify potential issues early on, and reduce the time and cost associated with traditional manual methods.

By integrating CARD into your workflow, you’re not just adopting a new tool—you’re optimizing your fleet repair services. It revolutionizes auto painting by providing precise color matching and ensuring consistent finishes, which is crucial for maintaining vehicle aesthetics and resale value. Moreover, it simplifies complex car body repairs by offering digital blueprints, making the process more accessible to technicians and reducing errors. Ultimately, CARD raises the bar for quality and efficiency in any automotive repair setting.

Choosing the Right Software for Your Needs

When integrating computer-aided repair design (CARD) into your workflow, selecting the right software is a crucial first step. Consider what specific needs your business has, whether it’s for vehicle repair or even car restoration after a fender bender. Some CARD software excels in 3D modeling and simulation, while others focus more on detailed measurement and design for body shop repairs.

Match the software to your team’s skill set and future goals. Ensure it offers features that align with your current processes as well as potential expansions. A robust CARD system not only streamlines existing practices but also enables new levels of precision and efficiency, ultimately enhancing the quality of your work in areas like body panel alignment and painting applications.

Seamlessly Integrating into Existing Workflows

Seamlessly Integrating Computer-Aided Repair Design into your existing workflows can significantly enhance efficiency and precision in both car repair shops and vehicle restoration facilities. This advanced technology allows for accurate digital measurements, enabling faster and more effective planning of automotive body work. By integrating computer-aided design (CAD) software, technicians can easily create detailed templates and layouts for repairs, ensuring consistency and reducing human error.

The benefits extend beyond straightforward repairs; CAD systems offer a comprehensive view of the entire process, from initial assessment to final touches. This holistic approach not only speeds up turnaround times but also improves communication among team members. For example, in automotive body work, real-time data sharing via digital platforms allows for better coordination between paint specialists, mechanics, and assemblers, leading to higher-quality vehicle restoration outcomes.

Integrating computer-aided repair design (CARD) into your workflow can significantly enhance efficiency and accuracy. By understanding the basics, selecting suitable software tailored to your needs, and seamlessly integrating it with existing processes, you can unlock the full potential of CARD. This approach ensures that repairs are not only faster but also more precise, ultimately leading to better outcomes for both technicians and customers alike.